Fabric and Thickness

生地は山本化学工業のSCS生地を使います。

生地厚は、1.5ミリ、2ミリ、3ミリ、5ミリ、6.5ミリ、8ミリ(受注生産)がございます。

Neoprene jersey materials

This material is made with polyester or nylon.

Pasting these polyester or nylon neoprene jersey materials onto rubber strengthens the material and offers various colors when used on the outer layer.

It also makes it easier to wear as it slides against the skin when used on the inner layer.

Elasticity: 180 – 380%

Water absorption: 0 – 5%

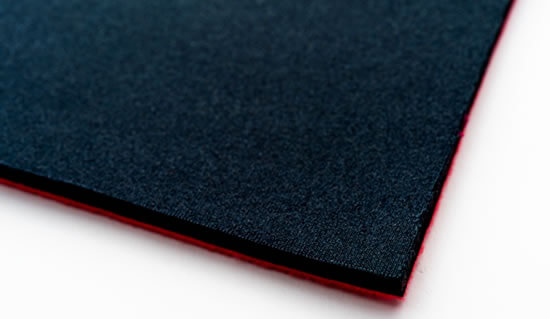

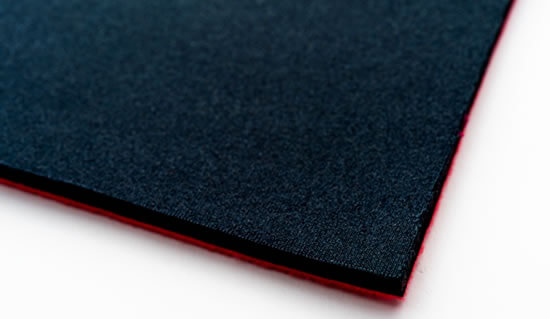

SCS (Super Composite Skin)

スムーススキンの表面に特殊加工「SCS(Super Composite Skin)」を施している。

親水性と疎水性をもつミセル構造の加工を施すことで、水に濡れると表面に水分子が皮膜し、低抵抗になることで、着脱や水の抵抗を下げることができます。

摩擦抵抗係数:0.32~0.021cdf

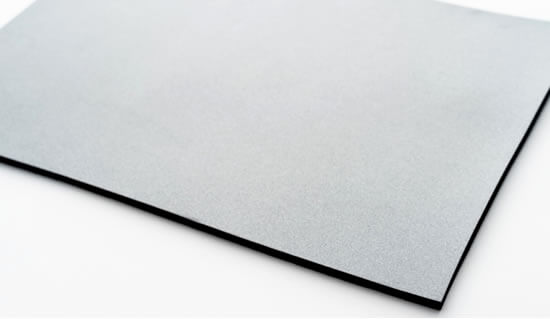

Skin

This material used on the surface of the rubber is called Smoothskin.The material is used for the inner and/or outer layer of the wetsuits, creating a smooth surface.

When used on the outer surface, it allows wetsuits to dry immediately, which can prevent divers from getting cold from wind chill out of the water.

When used on the inner surface, you can use powder or water to help put on the suit.

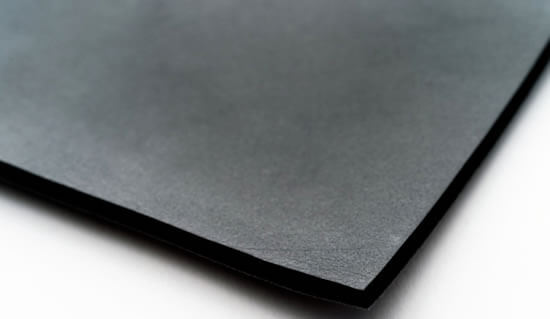

Lined with jersey material

Using this material on the inner surface of the wetsuits retains heat and brings a suede-like smooth feel against the skin.

It also has high water repellency.